A quick introduction to spectroscopy

Optical Spectroscopy is segmented into the wavelength regions covered by detection instruments and appropriate to the application. Generally, the wavelength regions are referred to as here:

- Ultraviolet (UV) 185nm – 400nm

- Ultraviolet/visible (UV/VIS) 200nm – 800nm

- Visible/near-infrared 400nm – 1200nm (VIS/NIR)

- Near-infrared (NIR) 800nm – 2500nm

- Mid-infrared (MIR) 2500nm – ~5000nm (5um)

- Spectrometry is vital for a wide range of applications.

Every form of matter interacts with light in ways specific to the atoms and molecules present, creating a unique optical spectrum. Another way to think of it is as a spectral fingerprint, and by using the right spectrometer, the user can identify the atoms or molecules present and even their concentration.

Optical spectrums are valuable in QA/QC applications as well as in safety and process control systems or in measuring pollutants or water saturation in agriculture. There are nearly endless applications beyond these for spectroscopy, making it a popular and excellent tool in many industries.

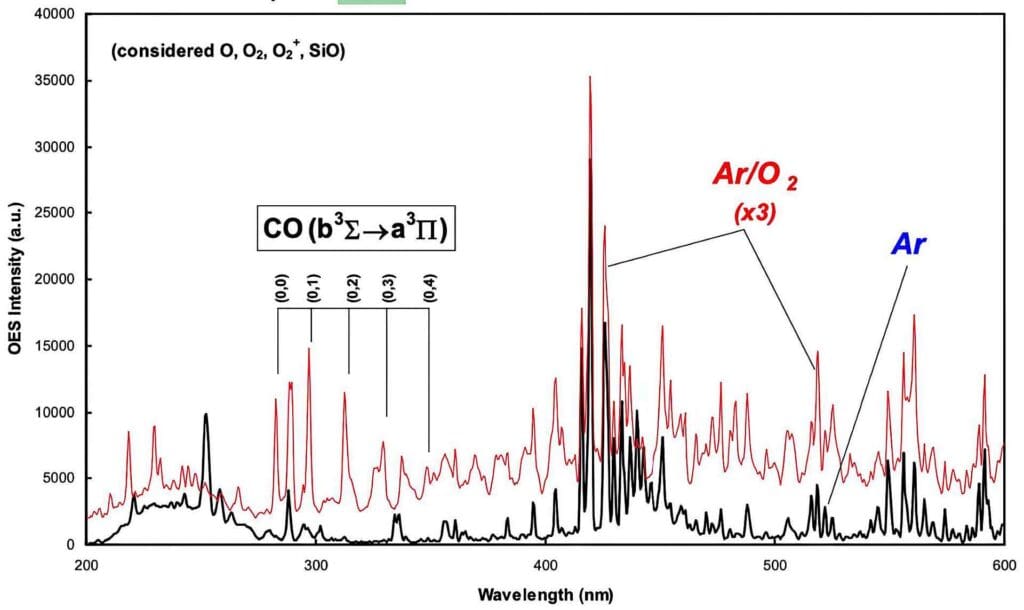

For example, a detector array is created by setting a group of detector strips together, with each one set to an independent output that’s related to the light impinging upon it. When the user knows which detector segments correlate to which wavelengths, they can create a data set showing the Intensity vs. Wavelength, such as the example here by FG Celii and JW Hosch:

Why Choose XSOF for Spectroscopy Applications?

At XSOF, we make custom fiber optic assemblies and cables to:

- Deliver the energy to the process/patient/instrument

- Collect the energy from the process/patient/source

- Both deliver and collect energy in the same unit

We are also responsible for designing and fabricating:

- Custom process interfaces, including high temp, vacuum, harsh environment

- Instrument interfaces

- Specialty cables to route energy within instruments or tools

XSOF assemblies present energy in particular ways to allow a particular measurement to be made. Configurations include Mapped, Random, Linear, Curved, Imaged, and Focused, just to name a few.